Modern communication networks can connect operators to sensors at remote sites inspections can be done from the control center, allowing them to see the condition of the assets in real-time. One of the biggest expenses that utilities have is rolling a truck to a site whether it’s for maintenance at a remote site, or emergency repair or replacement, truck rolls take man-hours away from resources and these can be significantly reduced with the tools that are now available. The cameras provide real-time situational awareness, allowing operators to diagnose problems without having to dispatch a crew to the site and also ensured safety procedures were being followed when they were on site. While the camera system provided automated security through motion detection and perimeter violation, operators could also take control of pan, tilt, zoom, (PTZ), cameras to inspect transformers, switches, etc. Operators soon discovered that having cameras allowed them to do inspections without having to send field technicians to the site. It has long been thought that the only purpose for video cameras at a substation was to provide physical security at the site. The health index score helps in asset management to track the condition of assets and to determine if any actions are needed to maintain, repair or replace equipment. As the sensors are reading information from the assets, the data is not only being presented in real-time but also digitized and stored so it can be used in multiple applications, such as in the calculation of an asset health index. Not only can the asset data be presented and monitored in real-time, but it can be stored in a historical database that can be used in predictive analytics to plan and prioritize maintenance, repair or replacement activities. The dashboard allows operators the ability to drill down to get more details on what caused the alarm, so they have the data on hand to make informed decisions. The alarm level could depend on specifications from the equipment manufacturer, but it may take into consideration other situations, such as weather conditions and load.

The operator sets the threshold parameters for the alarm analytics, allowing them to be in control of the system and tune it for their particular situation. The automation part provides alarms so even if the operator isn’t watching the dashboard they will be notified that something needs their attention. Sensors Provide a Long-Term View and an Immediate Status Real-time monitoring gives operators a live dashboard view of the state of their assets. Sensor technology can also allow the utility to perform remote inspections to make more efficient use of man and machine hours. To prevent the utility from being overloaded with the wealth of data from the field, there are also applications available to view the data in real-time and process it to determine health scores and predict when and how failures might occur. The development of both sensor technology and communications networks is now providing the means to deploy solutions that can track the health of assets and plan when maintenance should be scheduled to prevent failures.

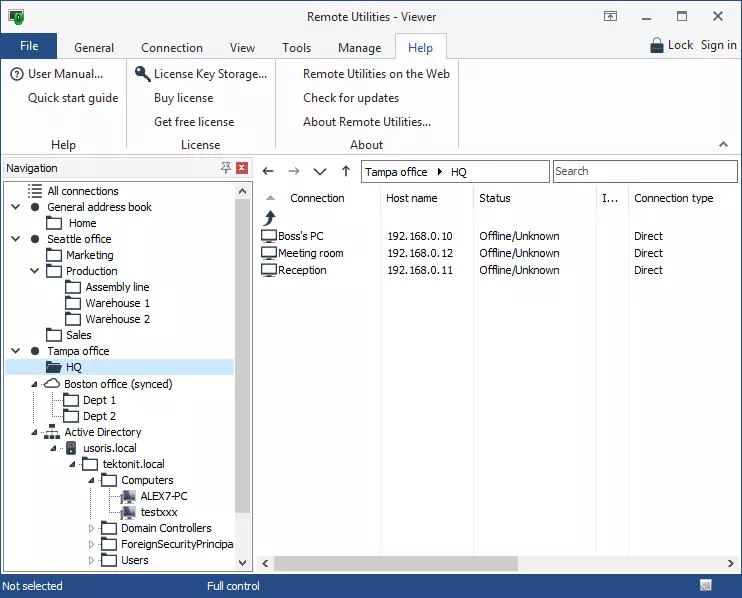

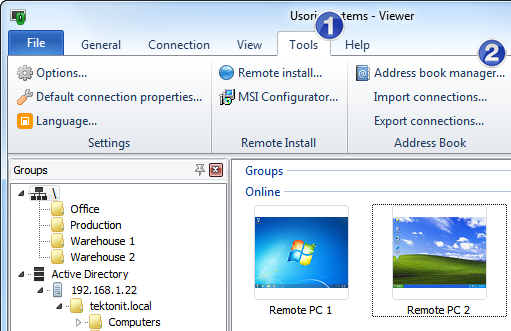

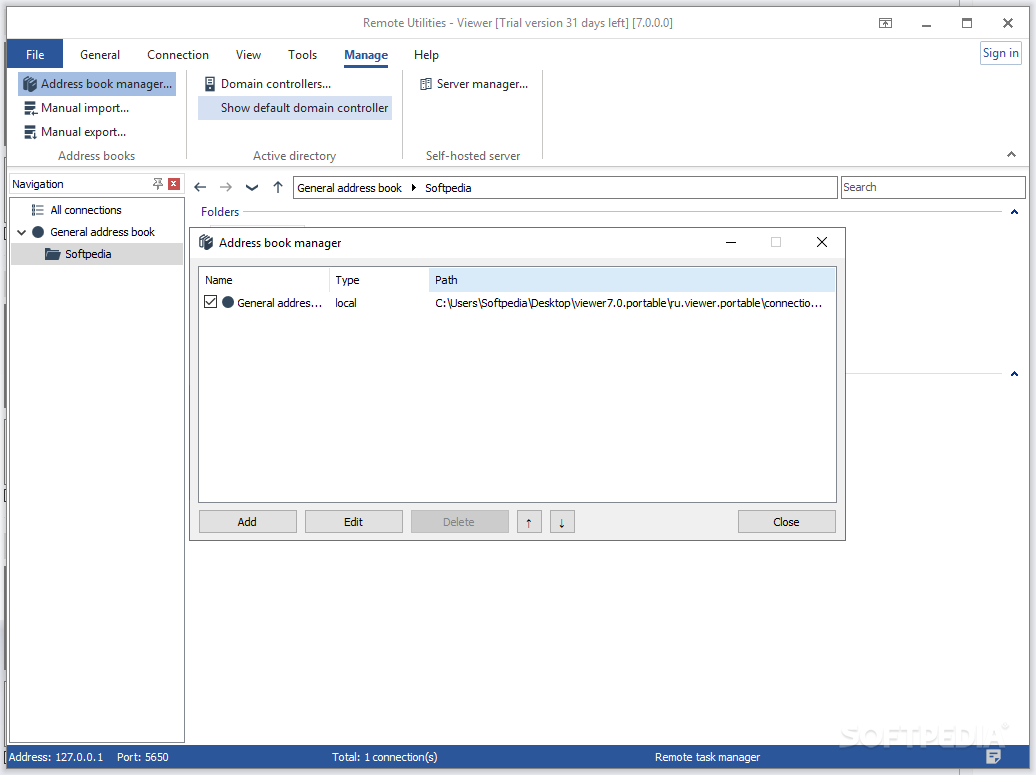

Remote utilities monitor orientation how to#

With the challenge of keeping costs under control and service reliability high, knowing how to prioritize maintenance and repairs to provide the most efficient and cost-effective results is a huge benefit. An electric utility’s assets must be maintained and repaired on a continuous basis to prevent equipment failures and outages and to keep the system operating safely.

A growing trend in the electric power utility industry is the automated monitoring of remote sites and assets.

0 kommentar(er)

0 kommentar(er)